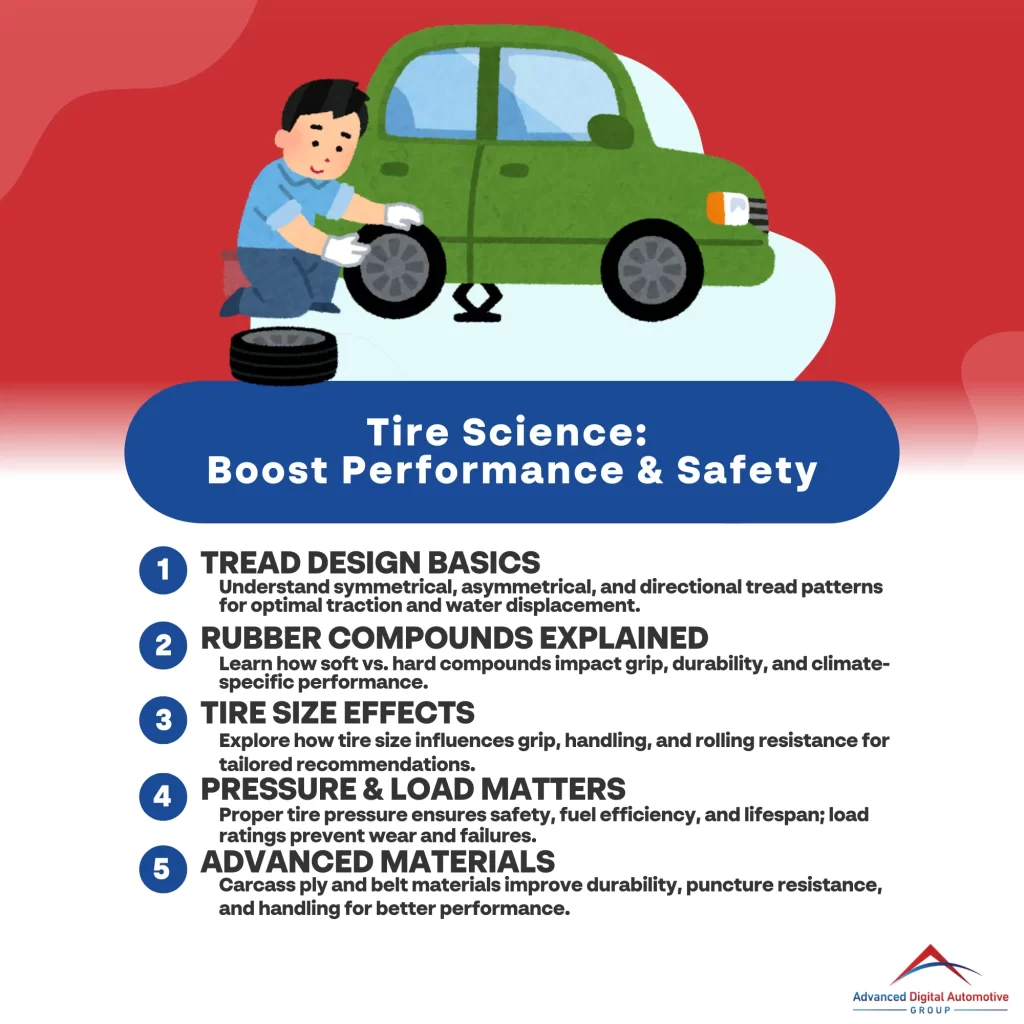

Understanding tire design is essential for your role as an auto repair professional. Tires consist of multiple layers, each influencing performance, from tread patterns that affect traction to rubber compounds that balance grip and durability. Carcass ply materials and construction impact puncture resistance and ride comfort. Proper tire size enhances stability but can increase rolling resistance. Tire pressure management is important; under or over-inflation affects wear and handling. Knowing these elements allows you to make informed recommendations and repairs. Explore how advanced tire features can further enhance your service offerings and improve customer satisfaction.

Key Takeaways

- Tire construction involves multiple layers and materials, influencing performance, durability, and handling characteristics essential for repair professionals to understand.

- Tread design significantly impacts traction and water displacement; knowing the differences between symmetrical, asymmetrical, and directional patterns is crucial for tire recommendations.

- Rubber compounds vary in softness and hardness, affecting grip and longevity; understanding these properties aids in selecting suitable tires for different climates.

- Maintaining proper tire pressure enhances safety, fuel efficiency, and tire life span; educating customers on its importance is vital for effective auto repair service.

- Familiarity with tire design variations, such as performance and all-terrain tires, enables better customer service and tailored recommendations based on specific driving needs.

The Foundation: Understanding Tire Construction

When it comes to tire performance, understanding tire construction is essential for auto repair professionals. Tire science reveals that a tire comprises multiple layers, including the tread, belts, sidewalls, and inner linings. Each layer plays a significant role in overall performance, durability, and safety. The tread design, for instance, directly influences traction, handling, and water displacement. You should familiarize yourself with various tire tread designs, as they cater to different driving conditions and vehicle types.

The tread patterns can be categorized broadly into symmetrical, asymmetrical, and directional designs. Symmetrical tread designs provide even wear and are suitable for various conditions, while asymmetrical designs enhance performance by separating wet and dry traction capabilities. Directional designs, on the other hand, promote better water evacuation, reducing hydroplaning risks.

Moreover, understanding how construction materials, such as rubber compounds and reinforcing materials, affect tire longevity and performance is vital. As you continue to develop your skills, remember that mastering tire construction not only improves your repair techniques but also enhances your ability to recommend the right tires for your clients’ needs.

Tread Patterns

Tread patterns are crucial in optimizing tire performance, directly influencing traction, handling, and overall vehicle safety. The tire tread design science focuses on how various patterns affect interaction with different road surfaces. You’ll encounter several types of tire designs, each tailored for specific driving conditions. For instance, symmetrical tread patterns offer balanced handling and are commonly found in passenger tires, while asymmetrical designs enhance cornering stability and wet traction.

Directional tread patterns, designed to channel water away, are important for maintaining grip on slippery surfaces. Understanding these designs allows you to recommend the right tire for your customers’ needs. Additionally, the depth and spacing of tread grooves play a significant role in performance; deeper grooves provide better traction in adverse conditions, while shallower grooves may enhance fuel efficiency on dry roads.

Rubber Compound

The performance of a tire isn’t solely determined by its tread pattern; the rubber compound also plays an essential role in how a tire interacts with various driving conditions. In tire science and technology, the rubber compound’s formulation affects grip, durability, and fuel efficiency. You’re probably wondering, why are tires made of rubber? The answer lies in rubber’s unique properties, such as its elasticity and resilience, which allow tires to deform and recover, providing ideal traction and comfort.

Different rubber compounds are engineered for specific performance characteristics. For example, a softer compound enhances grip but may wear quickly, while a harder compound may offer longevity but reduce traction, especially in wet conditions. As an auto repair professional, understanding the nuances of rubber compounds helps you recommend the right tires based on driver needs and local climate.

Moreover, advancements in tire technology have led to the inclusion of additives that improve performance metrics, such as rolling resistance and temperature stability. By grasping the importance of rubber compounds, you can better inform customers about tire choices that align with their driving habits and safety requirements.

Carcass Ply And Belt Materials

Understanding carcass ply and belt materials is vital for auto repair professionals as they greatly influence a tire’s structural integrity and performance. The science of tires shows that the carcass, typically made from polyester, nylon, or steel, forms the foundational layer of a tire, providing strength and flexibility. The number of plies affects both durability and ride comfort; more plies generally enhance stability but can increase weight.

Belt materials, usually composed of steel or fabric, reinforce the tread area. Steel belts improve puncture resistance and enhance handling, making them essential in high-performance tire designs. The arrangement of these belts plays a significant role in managing tire heat and wear, impacting overall performance and safety.

Moreover, the choice of materials directly influences factors like rolling resistance, which affects fuel efficiency. As an auto repair professional, understanding these elements allows you to assess tire conditions accurately and make informed recommendations for replacements or repairs. So, when evaluating tire integrity, consider the interplay between carcass ply and belt materials to guarantee peak vehicle performance and safety.

The Impact Of Tire Size On Performance

Often, tire size considerably influences a vehicle’s overall performance, affecting handling, stability, and fuel efficiency. Larger tires typically provide a larger contact patch, which enhances grip and stability, particularly during cornering. However, this can also lead to increased rolling resistance, impacting fuel efficiency negatively. On the other hand, smaller tires may reduce weight and rolling resistance, improving fuel economy but potentially sacrificing traction and stability.

The physics of tires dictates that the relationship between tire size and performance is complex. For instance, tire tread designs play an essential role in channeling water and providing traction. A wider tire might disperse water more effectively, reducing hydroplaning risk. Conversely, a narrower tire could push through standing water better, offering superior performance in certain conditions.

When selecting tire size, consider the balance between performance and efficiency. Choosing the right size not only enhances a vehicle’s handling characteristics but also contributes to ideal fuel consumption. As an auto repair professional, understanding these dynamics helps you guide clients in making informed decisions about tire replacements and upgrades.

Temperature And Load Ratings

Temperature and load ratings are critical factors that impact tire performance and safety. When evaluating car tire designs, you’ll notice that these ratings indicate how well a tire can withstand heat generated during operation and the maximum load it can bear. Each tire is tested under standardized conditions, and the results are marked on the sidewall, typically as a temperature rating (A, B, or C) and a load index.

Understanding these ratings is essential for you as an auto repair professional. Tires with low temperature ratings may degrade quickly under high-performance conditions, leading to reduced safety and life span. Similarly, if the load ratings are exceeded, you risk tire failure, compromising vehicle stability and control.

Different tire tread designs can also influence how well a tire manages heat and load. For instance, a tire designed for off-road use may have different characteristics compared to one intended for highway driving. By ensuring that customers select tires with appropriate temperature and load ratings aligned with their driving habits, you help them maintain peak performance and safety, reinforcing the importance of proper tire selection in your repair services.

The Role of Tire Pressure

Tire pressure plays an essential role in vehicle safety and performance, directly impacting handling, fuel efficiency, and tire longevity. Maintaining the correct tire pressure guarantees ideal contact with the road, which is vital for effective performance, particularly when considering what are the different types of tire tread designs. Under-inflated tires can lead to uneven wear and diminished traction, while over-inflation can cause a harsh ride and increased susceptibility to damage.

As you explore new tire designs, remember that tire pressure specifications can vary. Each design may have unique requirements based on tread patterns and intended use. For instance, performance tires may demand higher pressures for maximum responsiveness, while all-terrain tires could benefit from lower pressures to enhance grip on uneven surfaces.

To promote safety and efficiency, regularly check tire pressure and adjust it according to the manufacturer’s recommendations. This practice not only prolongs tire life but also maximizes fuel efficiency, reducing overall operating costs. By understanding the relationship between tire pressure and design, you can better serve your customers and improve their driving experience.

Frequently Asked Questions

How Do Tire Designs Influence Fuel Efficiency?

Did you know that tire design can impact fuel efficiency by up to 15%? By choosing low rolling resistance tires, you reduce energy loss, enhance vehicle performance, and ultimately save on fuel costs during your drives.

What Role Does Aerodynamics Play in Tire Performance?

Aerodynamics greatly impacts tire performance by reducing drag and improving stability at higher speeds. You’ll notice enhanced fuel efficiency and handling characteristics as optimized tire shapes minimize air resistance, leading to better overall vehicle dynamics and safety.

How Can Tire Design Affect Road Noise Levels?

Tire design greatly affects road noise levels through tread patterns, rubber compounds, and overall construction. You’ll find optimized designs can minimize vibrations and sound, enhancing ride comfort while maintaining performance characteristics essential for driving experience.

Are There Eco-Friendly Tire Design Options Available?

Over 30% of tire manufacturers now offer eco-friendly options. You can choose tires made from sustainable materials, which reduce environmental impact while maintaining performance. These designs often enhance fuel efficiency and minimize waste during production.

How Do Different Tire Brands Compare in Design Quality?

When comparing tire brands, you’ll notice variations in design quality influenced by materials, tread patterns, and manufacturing processes. Evaluating performance metrics and customer feedback can help you identify the best options for your needs.

Conclusion

In the intricate dance of tire design, each element plays a crucial role, much like the components of a finely tuned engine. By mastering the nuances of tread patterns, rubber compounds, and tire construction, you empower your customers with choices that enhance safety and performance. Think of yourself as a conductor, harmonizing these elements to create a symphony of driving excellence. Embrace this knowledge, and you’ll not only elevate your service but also guarantee every journey is a safe and efficient one.